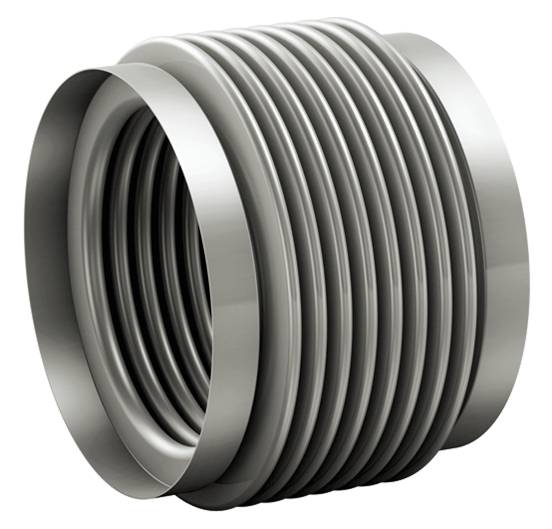

Flexible Hoses, Flex Pipes & Bellows

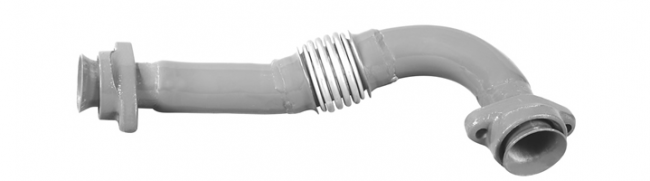

SOYLU, Ø22 mm – Ø300 mm sizes to produce flexible pipes with polygonal type of nesting is capable of all this in addition to being flexible pipes fixed-length 2 meters to 10 meters and it is possible to manufacture rolls Soylu exhaust systems you can order reference numbers of these products contained in catalogs.

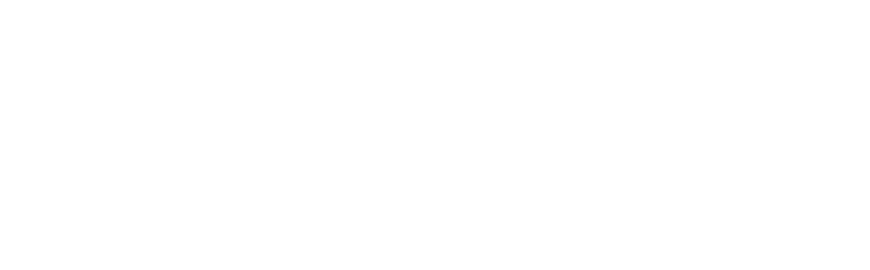

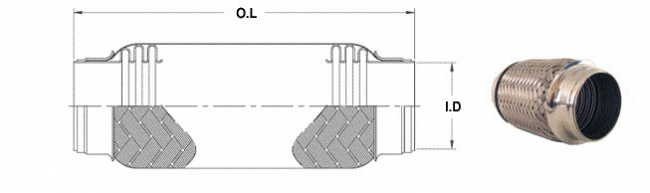

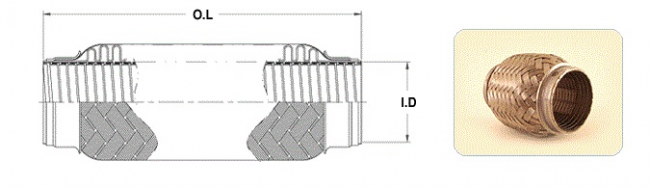

Ø32 mm – Ø356 mm size range, and lengths ranging from bellows type 103 – 400 mm or interior and exterior braided flexible conduits are product range consists of.

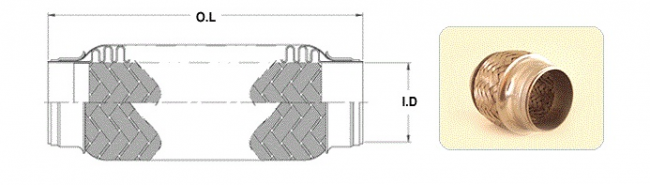

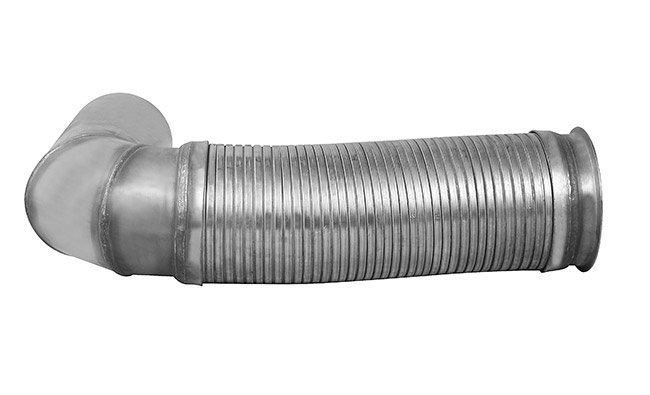

SOYLU, integrated into the highest-quality locking flexible pipes on the market uses Flexible pipes, exhaust systems, engine vibration, the engine is used to absorb motion and heat expansion.

A wide range of dimensions

Flexible pipes, exhaust pipe clamp attached to the separate or integrated as part of a unit can be supplied in various sizes.

SOYLU, three standard material, (Ø22 mm – Ø300 mm) offers a wide range of flexible pipes and Flexible tubes in diameters with Seam data, see

Flex Pipe installation and usage is extremely important.

Installation and use is of crucial importance

Installation and use of flexible pipes is of crucial importance to the durability and functionality of the flexible unit.

Flexible pipes are designed to absorb mainly lateral and angular movements. It is not recommended to use flexible pipes to absorb torsional movement.

Installation guidelines

In order to maximise longevity of any flexible installation, it is recommended to follow the installation guidelines. These imply that any flexible connection will, depending on the actual movements to absorb, be in the area of 2-3 times the diameter of the flex/pipe work.

Please note that a flexible pipe can be extended approx. 25\%, and the mid position is half of the extension (12.5\%).

The flex connection must be located in a mid position allowing the interlock structure to move equally in both lateral directions.